Antibacterial masterbatch: What do you know?

Abstract

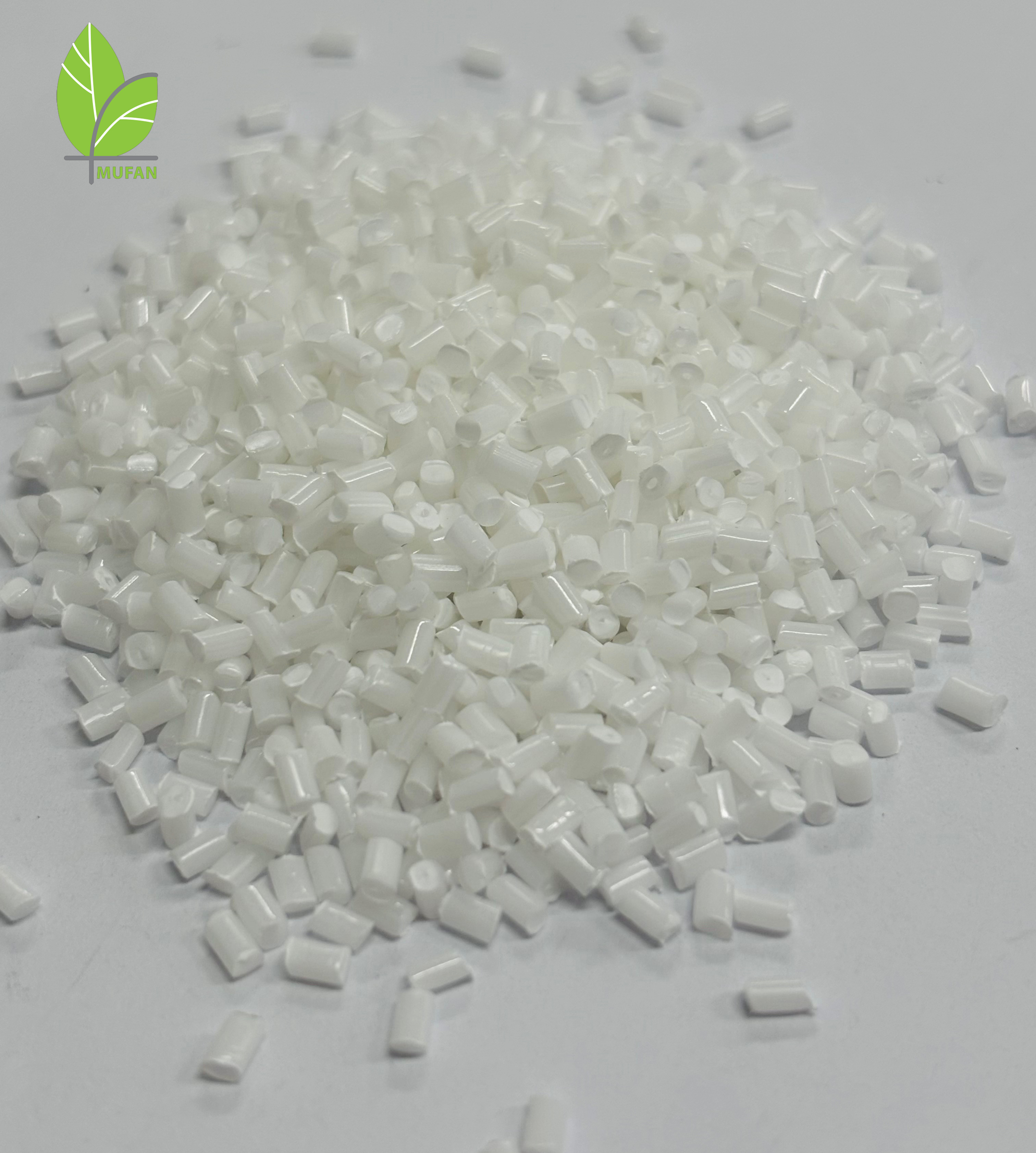

Antibacterial Masterbatch is a high- concentration functional masterbatch made by dispersing antibacterial agents into a carrier resin via a special process. When added to PP, PE, PS, TPU, etc., at our recommended ratio, it achieves a 99.9% antibacterial rate against E. coli, Candida albicans and Staphylococcus aureus, endowing the final product with long - lasting antibacterial properties that effectively inhibit the growth of bacteria, fungi and other microorganisms. It can be directly blended with the base material without altering existing production processes.

Outstanding Advantages :Antibacterial masterbatch effectively inhibits the growth of bacteria, fungi and other microorganisms by releasing antibacterial components, reducing bacterial growth on product surfaces, extending service life, and ensuring user health.

Application Areas:

- Medical field: Medical equipment, surgical instruments, medical packaging, protective supplies,etc.

- Food packaging: Food packaging films, fresh-keeping boxes, etc.

- Household goods: Various tableware, children's toys, bathroom supplies, etc.

- Public facilities: Seats, handrails, and pull rings on public transportation vehicles.

- Textiles: Antibacterial fibers, medical protective clothing.

- Automotive field: Automotive interior plastic parts, automotive seat fabrics, air conditioning filters, etc.

- Electronics and electrical appliances: White appliances, mobile phone protective films, keyboard shells, etc.

- Building materials: Antibacterial floors, wall coatings.

Future Development Trends :

Composite functions: Masterbatches with multiple functions such as antibacterial, antiviral, and mildew-proof.

Nanotechnology: Using nano-silver, zinc ions to improve antibacterial efficiency and dispersibility.

Conclusion: Antibacterial masterbatches are widely used in many areas.They‘re silent yet powerful has quietly integrated into every corner of our lives, from food packaging to building materials, from daily necessities, textiles, white appliances, electronics, medical fields to high-tech products, guarding our health and future everywhere.

Key words:

Antibacterial Masterbatch

Antimicrobial Masterbatch

Antimicrobial Plastic Additive

Long-lasting Microbial Protection Masterbatch

Bacteria-inhibiting Additive