Applications of organic black masterbatch

Abstract

Specific applications of organic black masterbatch include:

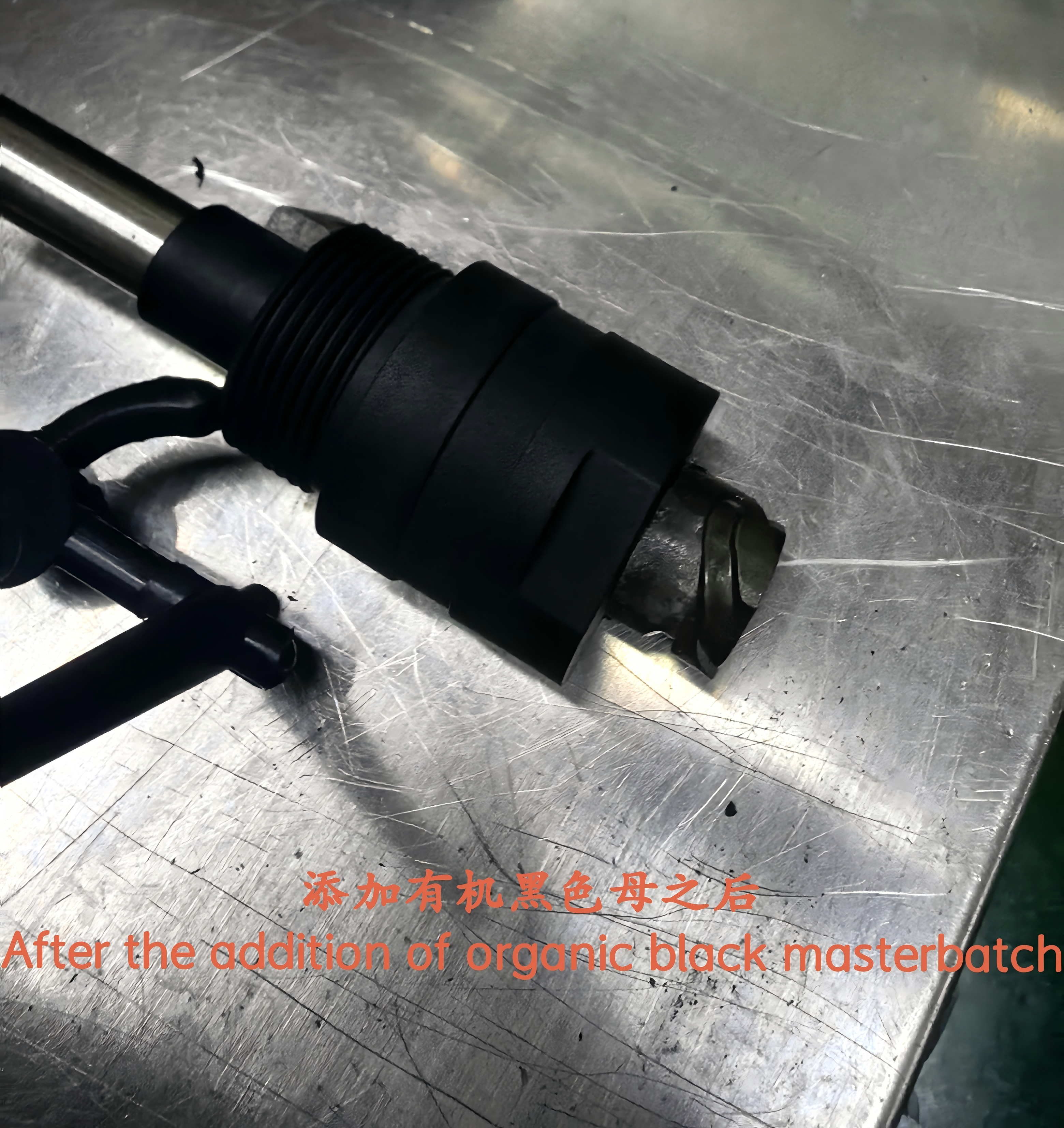

1. Enhancing product appearance quality

Organic black masterbatch provides a uniform and rich black color, covering any flaws or floating fibers in the raw materials, improving surface smoothness, and meeting high-end appearance requirements. This is particularly important for industries such as automotive interior and exterior parts, appliance casings, consumer electronics, and office supplies.

2. Improving optical properties and UV resistance

By adding special organic dyes or pigments, organic black masterbatch can enhance UV resistance while providing excellent hiding power, extending the outdoor service life of products, especially suitable for automotive parts and outdoor decorations.

3. Enhanced electrical performance and electromagnetic shielding

Some organic black masterbatches, combined with conductive pigments, can impart a certain degree of conductivity to the product, achieving electromagnetic shielding (EMI) functionality, used in electronic casings, connectors, etc.

4. Improving mechanical and processing properties

Properly proportioned organic black masterbatch can improve the flowability of PA, reduce defects such as burrs and shrinkage during processing, and contribute to the precision and quality of the product. In addition, organic masterbatch can also improve the impact strength and surface hardness of the material to a certain extent.

5. Safe, environmentally friendly, and non-migratory

High-quality organic black masterbatch uses non-toxic, non-migratory dyes and carrier systems to meet the stringent safety requirements of food contact and medical applications.

6. Expanding special performance applications

Organic black masterbatch can be designed to add flame retardants, antistatic agents, UV inhibitors, heat-resistant agents, and other multifunctional additives as needed, giving products multiple properties to meet different special environmental needs.

7. Color stability and weather resistance

Black masterbatch made with high-quality organic pigments has good light and weather resistance, strong stability, and is suitable for long-term use or application in various environmental conditions.

8. Environmental protection and regulatory compliance

By selecting environmentally friendly dyes and carrier systems, organic black masterbatch can meet the requirements of environmental regulations such as RoHS and REACH, suitable for use in electronics, electrical appliances, packaging, and pharmaceutical industries.

Summary:

The application of organic black masterbatch in PA glass fiber reinforced materials is not limited to covering floating fibers and improving appearance. Its multi-functionality and controllability make it have broad application prospects in many fields such as automobiles, electronics, home appliances, packaging, and construction. With the continuous development of high-performance materials and environmental protection requirements, the customization and multi-functionality of black masterbatch will become an important trend in the future, bringing better and more environmentally friendly performance to plastic products.

Key words:

Organic Black Masterbatch

Aniline Black Masterbatch

Functional Masterbatch