Why choose high-dispersion masterbatch?

Release time:

2025-02-19

Author:

Source:

Abstract

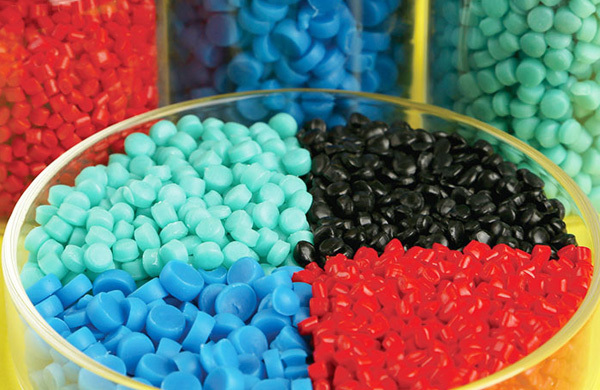

High-dispersion masterbatches have excellent dispersibility, resulting in stronger pigment coloring power and brighter, more vibrant colors.

Advantages of high-dispersion masterbatches in production and processing:

Uniform product color, virtually no agglomerated color points; improved product yield;

Significantly reduces screen changeover time and frequency;

Increases production speed and capacity. According to Customer Feedback, when using STD white masterbatch, the production line speed can reach 140m/min, while competitors only reach 40m-50m/min.

Recommend Reading

Marble Effect Masterbatch: A Dual Breakthrough—Driving Technological Core and Industry Empowerment

2025-11-24

2025-10-22

Applications of organic black masterbatch

2025-08-07